Free Welder Performance Qualification Record Template

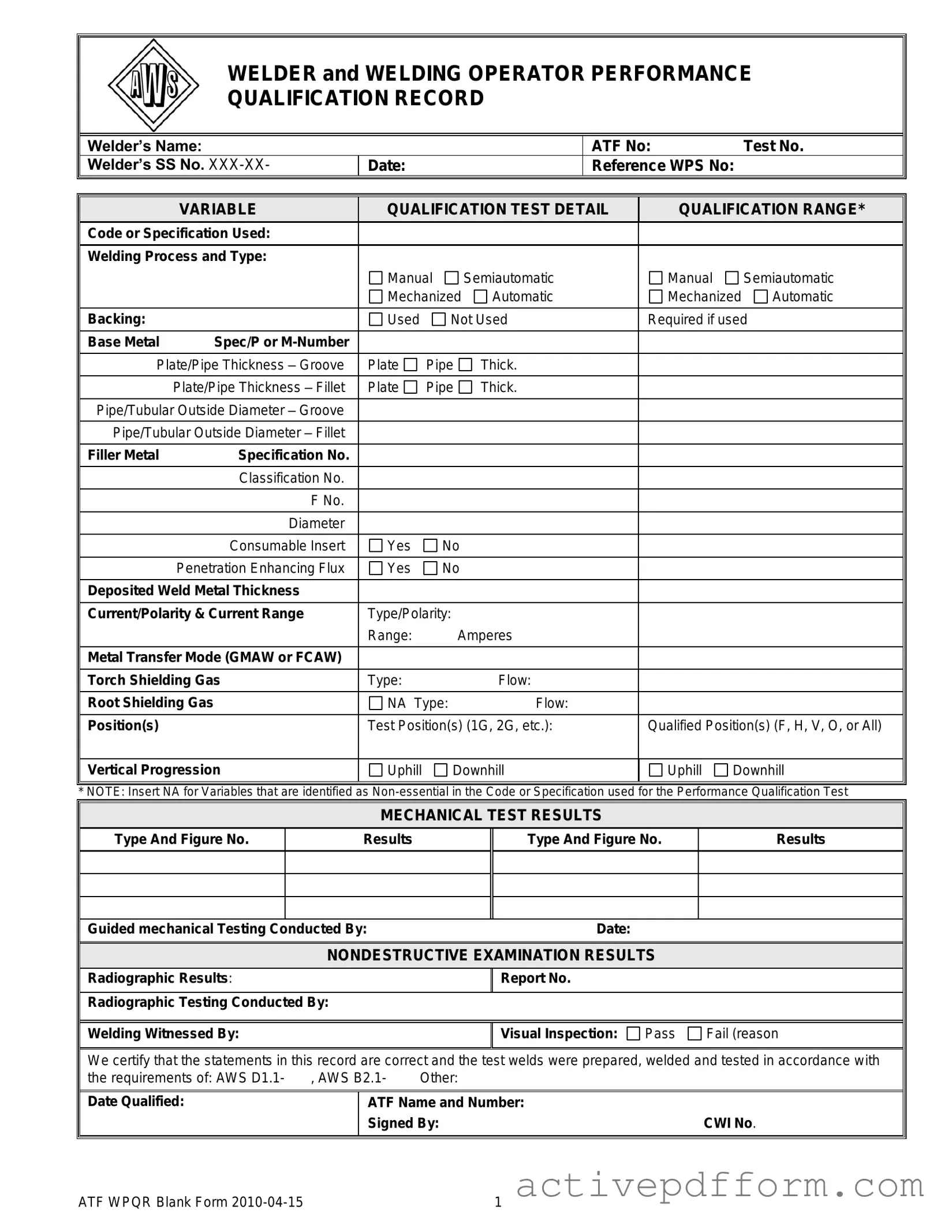

The Welder Performance Qualification Record (WPQR) form is an essential document used to verify a welder's skills and qualifications. This form captures critical information about the welder, including their name, identification numbers, and the specific tests they have completed. It outlines the details of the welding process, including the type of welding performed—whether manual, semiautomatic, or automatic—as well as the specifications and codes that govern the qualifications. The WPQR includes a section for variable qualifications, detailing the base metal specifications, thickness, and filler metal classifications used during the tests. Furthermore, it records mechanical test results and non-destructive examination outcomes, ensuring that all aspects of the welding process are documented thoroughly. The form also certifies that the welding was conducted in accordance with industry standards, including AWS specifications. Ultimately, the WPQR serves as a comprehensive record of a welder's capabilities, providing employers and regulatory bodies with the necessary assurance of quality and compliance.

Document Specifics

| Fact Name | Detail |

|---|---|

| Purpose | The Welder Performance Qualification Record form certifies a welder's ability to perform specific welding tasks according to industry standards. |

| Welder Identification | It requires essential information about the welder, including name, ATF number, and Social Security number. |

| Test Information | The form includes a test number and the reference Welding Procedure Specification (WPS) number used during qualification. |

| Qualification Range | It outlines the qualification range, detailing the types of welding processes and base metal specifications. |

| Mechanical Testing | Results from mechanical testing are documented, showing the effectiveness and quality of the welds produced. |

| Non-Destructive Examination | Radiographic results and visual inspection outcomes are recorded to ensure the integrity of the welds. |

| Certification | The form is certified by a qualified individual, confirming that the welding meets the necessary standards. |

| State-Specific Regulations | Some states may have specific laws governing the use of this form, such as compliance with local building codes or safety regulations. |

| Expiration and Renewal | Welder qualifications may have an expiration date, requiring periodic renewal to ensure ongoing competency. |

Similar forms

- Welding Procedure Specification (WPS): Similar to the Welder Performance Qualification Record, the WPS outlines the specific procedures and parameters for welding. It details the materials, techniques, and equipment to be used, ensuring consistency and quality in welding operations.

- Procedure Qualification Record (PQR): The PQR documents the results of tests conducted to verify that a specific welding procedure can produce welds that meet defined standards. Like the Welder Performance Qualification Record, it serves to validate the effectiveness of welding practices.

- Certificate of Compliance: This document certifies that a product or service meets specific requirements. It parallels the Welder Performance Qualification Record by confirming that a welder's qualifications align with industry standards and regulations.

- Non-Disclosure Agreement Form: This form is essential for protecting confidential business information among parties involved. Utilizing this Arizona PDF Forms will help ensure that all sensitive information remains secure and that both parties uphold their confidentiality obligations.

- Inspection Report: An inspection report records the findings from a quality inspection of welded joints. It is similar to the Welder Performance Qualification Record in that both documents provide evidence of compliance with standards and specifications.

- Material Test Report (MTR): The MTR provides details about the materials used in welding, including their properties and compliance with specifications. This is akin to the Welder Performance Qualification Record, which also references material specifications relevant to the welding process.

- Welder Certification Card: This card serves as proof that a welder has successfully completed the necessary training and testing to perform welding tasks. It is similar to the Welder Performance Qualification Record, as both confirm the qualifications of the welder.

- Non-Destructive Testing (NDT) Report: The NDT report documents the results of tests conducted to evaluate the integrity of welded joints without damaging them. This report shares similarities with the Welder Performance Qualification Record by providing assurance that welds meet required standards.

Welder Performance Qualification Record Example

WELDER and WELDING OPERATOR PERFORMANCE

QUALIFICATION RECORD

|

Welder’s Name: |

|

|

|

|

ATF No: |

|

Test No. |

||||||

|

Welder’s SS No. |

|

Date: |

|

|

Reference WPS No: |

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|||||

|

|

VARIABLE |

|

|

QUALIFICATION TEST DETAIL |

|

|

QUALIFICATION RANGE* |

|

|||||

|

Code or Specification Used: |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Welding Process and Type: |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

Manual |

Semiautomatic |

|

|

Manual |

|

Semiautomatic |

|||

|

|

|

|

|

Mechanized |

Automatic |

|

|

Mechanized |

Automatic |

||||

|

|

|

|

|

|

|

|

|

|

|||||

|

Backing: |

|

|

|

Used |

Not Used |

|

|

Required if used |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Base Metal |

Spec/P or |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

Plate/Pipe Thickness – Groove |

|

Plate |

Pipe |

Thick. |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

Plate/Pipe Thickness – Fillet |

|

Plate |

Pipe |

Thick. |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Pipe/Tubular Outside Diameter – Groove |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Pipe/Tubular Outside Diameter – Fillet |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Filler Metal |

Specification No. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Classification No. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

F No. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Diameter |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Consumable Insert |

|

Yes |

No |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Penetration Enhancing Flux |

|

Yes |

No |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Deposited Weld Metal Thickness |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

Current/Polarity & Current Range |

|

Type/Polarity: |

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

Range: |

Amperes |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Metal Transfer Mode (GMAW or FCAW) |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

Torch Shielding Gas |

|

Type: |

|

Flow: |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

||||

|

Root Shielding Gas |

|

NA Type: |

Flow: |

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

||||||

|

Position(s) |

|

|

|

Test Position(s) (1G, 2G, etc.): |

|

|

Qualified Position(s) (F, H, V, O, or All) |

||||||

|

|

|

|

|

|

|

|

|

||||||

|

Vertical Progression |

|

Uphill |

Downhill |

|

|

Uphill |

Downhill |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

* NOTE: Insert NA for Variables that are identified as

|

|

|

|

MECHANICAL TEST RESULTS |

|

|

||

|

Type And Figure No. |

|

|

Results |

|

Type And Figure No. |

Results |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Guided mechanical Testing Conducted By: |

|

Date: |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

NONDESTRUCTIVE EXAMINATION RESULTS |

|

|

|||

|

Radiographic Results: |

|

|

|

Report No. |

|

|

|

|

|

|

|

|

|

|

||

|

Radiographic Testing Conducted By: |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Welding Witnessed By: |

|

|

|

Visual Inspection: Pass |

Fail (reason |

) |

|

|

|

|

|

|||||

|

We certify that the statements in this record are correct and the test welds were prepared, welded and tested in accordance with |

|||||||

|

the requirements of: AWS D1.1- |

, AWS B2.1- |

Other: |

|

|

|||

|

|

|

|

|

|

|||

|

Date Qualified: |

|

ATF Name and Number: |

|

|

|||

|

|

|

|

Signed By: |

CWI No. |

|

||

|

|

|

|

|

|

|

||

ATF WPQR Blank Form |

|

|

1 |

|

|

|||

Understanding Welder Performance Qualification Record

What is a Welder Performance Qualification Record (WPQR)?

A Welder Performance Qualification Record is a document that certifies a welder's ability to perform specific welding tasks. It details the qualifications of the welder based on tests they have completed, ensuring they meet industry standards. This record is crucial for employers to verify a welder's skills and for welders to showcase their qualifications.

Who needs to complete a WPQR?

Welders and welding operators need to complete a WPQR. This form is especially important for those working in industries that require certified welding, such as construction, manufacturing, and shipbuilding. Completing the WPQR demonstrates that the welder has the necessary skills to perform specific welding tasks safely and effectively.

What information is included in the WPQR?

The WPQR includes the welder's name, identification numbers, the date of testing, and details about the welding process used. It also outlines the materials involved, the types of tests conducted, and the results of those tests. This comprehensive information helps ensure that all qualifications are documented clearly.

What types of welding processes are covered?

The WPQR covers various welding processes, including manual, semiautomatic, mechanized, and automatic methods. Each process has specific requirements and qualifications, which are documented in the record. This variety allows for a wide range of welding applications to be certified.

How long is a WPQR valid?

The validity of a WPQR can vary based on company policies and industry standards. Generally, it remains valid as long as the welder continues to work in the same position and uses the same techniques. If a welder changes processes or materials, they may need to retake the qualification tests and update their WPQR.

What is the role of non-destructive examination results in the WPQR?

Non-destructive examination (NDE) results are essential for validating the quality of the welds. These tests, such as radiographic or visual inspections, help ensure that the welds meet safety and quality standards. The results are documented in the WPQR to provide evidence of the weld's integrity.

How do I obtain a WPQR?

To obtain a WPQR, a welder typically needs to complete a qualification test through a certified organization or employer. After passing the test, the organization will fill out the WPQR form, documenting the welder's qualifications. It's important to work with a reputable testing facility to ensure the qualifications are recognized.

Can I use a WPQR from a different employer?

Using a WPQR from a different employer may not be straightforward. Each WPQR is specific to the welder's qualifications under particular conditions set by the employer. If you change jobs, your new employer may require you to undergo their qualification process, even if you have a valid WPQR from a previous employer.

What should I do if I need to update my WPQR?

If you need to update your WPQR, you should contact the organization that issued it. You may need to retake qualification tests if you have changed welding processes, materials, or positions. Keeping your WPQR current is essential for maintaining your qualifications and employment opportunities.

Dos and Don'ts

When completing the Welder Performance Qualification Record form, it is important to follow certain guidelines to ensure accuracy and compliance. Here are four things you should and shouldn’t do:

- Do provide accurate personal information, including the welder’s name and identification numbers.

- Do ensure that all test details are filled out completely, including the welding process and material specifications.

- Don’t leave any sections blank unless they are marked as non-essential; this could lead to delays in processing.

- Don’t forget to have the form signed by the appropriate certifying individual to validate the qualification.

Check out Common Templates

Soccer Player Evaluation Form - Excellent tactical awareness; reads the game astutely and shows great decision-making ability under pressure.

Simple Boyfriend Application Form - Nature lover who enjoys hiking and outdoor activities.

The New York DTF-84 form is an application for Qualified Empire Zone Enterprise (QEZE) Sales Tax Certification, designed for businesses recognized by Empire State Development. This form is essential for companies that aim to receive sales tax benefits, provided they meet specific eligibility requirements. It is crucial to submit the completed form along with the necessary documentation to ensure proper processing and access to the available tax benefits, which can be found at nytemplates.com/blank-new-york-dtf-84-template.

Direct Deposit Form Example Filled Out - Fill out the ownership section based on your account's status.